Theft and robbery of merchandise are, unfortunately, problems faced by virtually all stores, becoming a major obstacle during times of economic instability. Furthermore, damage and lack of organization can also lead to inventory losses.

To solve this issue, inventory control is essential. In today's post, we've put together practical and effective tips to help you prevent theft and other incidents from occurring in your iron and steel store, preventing inventory losses. Let's dive in!

What comes in and out of the store, what needs to be purchased, where each item is, how many volumes you have of each material: these and many other points must be evaluated so that you truly have full control over your inventory.

Sounds like an impossible task? Quite the opposite! You have the opportunity to count on a brilliant assistant in this task: an inventory management system. Capable of recording and analyzing all the data related to your iron and steel store's inventory, the system will allow you to digitize all this information.

This way, in addition to keeping this important data secure in the system, you'll also save time and effort managing your inventory. And the benefits go even further, as the system will prevent the purchase of already existing products and allow you to analyze sales flows for more strategic purchasing.

It's easy to understand why this is crucial to preventing inventory losses in your store, right? If you don't know what's in and what's out of stock, it's virtually impossible to identify what's gone missing, or when it happened.

Therefore, whether through the management system or other strategies, it's essential that you know exactly what products are coming in and out of stock. This allows your team to immediately identify if any items are missing and then proceed with the investigation to determine the cause.

Furthermore, it's crucial to remember that when it comes to iron and steel, the rule is clear: first in, first out! To prevent your products from oxidizing, your inventory must be constantly replenished.

Therefore, selling newer products while keeping older ones in stock is a serious mistake, but still very common. This only generates unnecessary losses, so be very careful to sell older products as soon as possible.

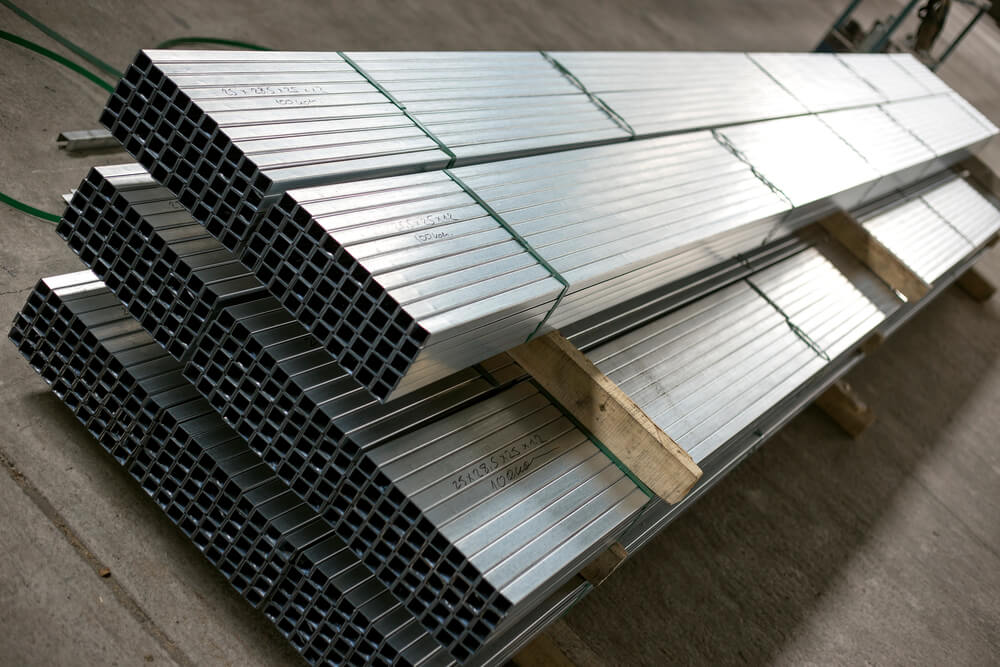

Okay, you know everything that comes in and out of your warehouse, but what's the condition of the products inside? If the inventory isn't internally organized and categorized, product loss becomes a very real possibility.

This disorganization can lead to a product being incorrectly classified as sold, for example. Another possible situation is that you can't find a product requested by a buyer, and thus lose a sale! In other words, inventory clutter creates complications that go beyond theft and robbery.

Another major cause of inventory losses is product damage. When stored safely, according to the manufacturer's recommendations, they will last undamaged for the entire period before being sold. To ensure your inventory is always up to date, conduct quarterly audits and take a complete inventory.

As you've seen, to avoid inventory losses, it's essential to keep inventory under control and with up-to-date data, leveraging technology to optimize your work. Want more tips like these for your iron and steel shop? Subscribe to our newsletter and stay up to date with all our content!