Choosing the right materials is a fundamental step for the success of any project. Furthermore, it's important to know how to apply these materials correctly. A good example of this is steel cutting and bending, processes that are essential for ensuring the quality of a structure.

Even for small-scale projects, it's essential to use custom steel parts, as this will impact the project's quality and strength. Understanding how the steel cutting and bending process works can help you make future decisions.

So, read on and see what you need to know about cutting and bending steel.

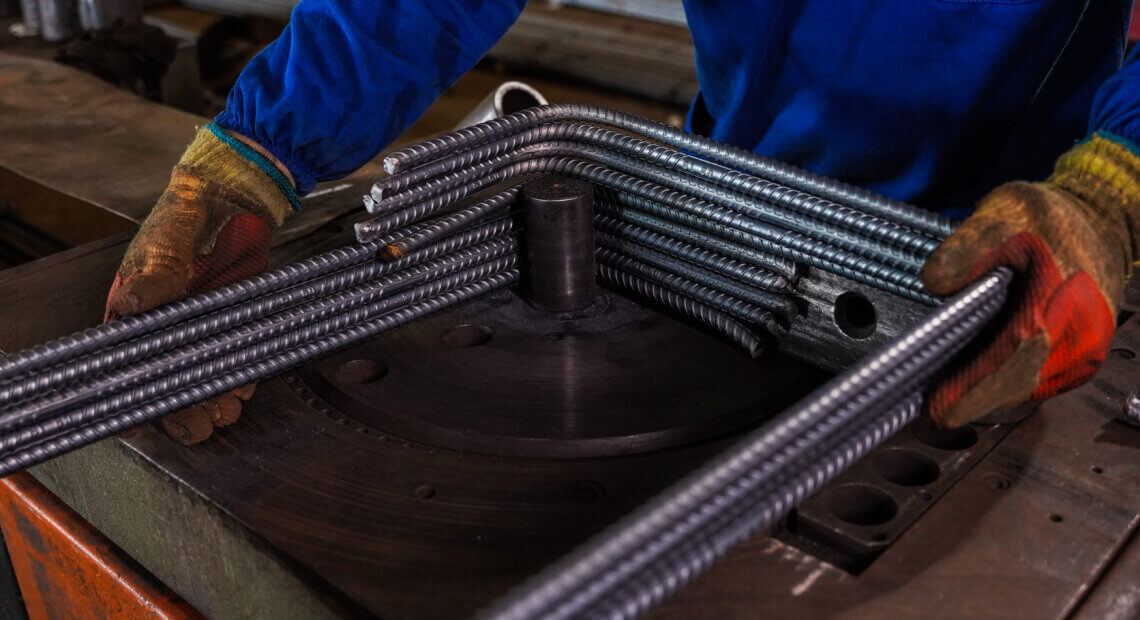

As the name suggests, steel cutting and bending are the processes that transform steel rebar into custom-made parts. Cutting gives the part the correct length for use, while bending creates the ideal shape.

These two steps are essential for creating purpose-built steel components. Because these parts are not conventional, many must be custom-ordered. However, you can also use your own tools to make the cuts during construction.

With the right steel cutting and bending techniques, you can significantly improve the performance of your project. Here are some of the main benefits.

The more complex a construction, the more important it is to have custom-made parts for each purpose. Having steel components in the right shape is essential to ensuring adequate support for buildings, especially when it comes to rebar and tiles of galvanized steel.

When cutting and bending steel, you can adjust the dimensions of each piece to meet very specific needs within your project. This allows you to use these components for repairs or even to assemble less conventional structures.

Other issues that arise during construction include overall cost and material waste. If you don't use custom steel parts, you'll likely need to make modifications during construction, discarding more material than necessary in the process.

With steel bending, it's possible to utilize the majority of the part, avoiding waste. This factor impacts the overall project cost and, in some cases, even allows us to offer more competitive prices to customers.

The greater the quantity of material used in a project, the more important it is to plan its proper storage, and this task becomes more complex if the parts are oversized.

When steel rebar is cut and bent, it can be stored in smaller spaces. Besides avoiding logistical issues, you can more easily protect these components from external factors that can wear them down, such as rain.

Optimizing the tasks performed on-site is essential for faster service delivery. In this sense, ordering steel cutting and bending separately allows you to start your work with the right components, speeding up the construction process. This also reduces the risks inherent in the construction process. civil construction and leaves your customers more satisfied.

The steel cutting and bending process can be performed in different ways. See here the main methods and their advantages.

This is the most traditional method, using a high-speed saw to cut the steel pieces. Because it's quite simple, saw cutting is quick and easy to use, making it ideal for thicker pieces. It's also a low-cost option.

On the other hand, a saw may not make a perfect cut, leaving grooves at the ends. Therefore, it's important to clean all parts and use a sander to achieve the correct shape.

Laser cutters are increasingly used to cut steel. Cutting is done by applying the laser to heat and split the piece, creating a thin slit in its surface.

This tool is highly precise and efficient, ideal for creating fine details on a steel part. However, the process must be performed by specialists using the appropriate equipment.

It's also possible to cut steel rebar using a concentrated jet of water. In many cases, the water is mixed with other abrasive components to facilitate proper cutting of the steel. This method is very effective, suitable for components of varying thicknesses, and ideal for cutting and bending. resistant steel.

Oxyfuel cutting involves projecting a jet of pure oxygen onto a heated steel rebar. In some cases, the oxygen is mixed with combustible materials, such as acetylene. This provides a clean cut, as the heated steel is more malleable. Furthermore, the method leaves less residue.

After cutting, the steel must be bent to achieve the correct shape for use. In some cases, the process is simple, such as when creating profiles. But other situations, such as parts that involve multiple bends, are more complex. Bending can be done manually or with the help of dedicated equipment.

THE Aço Cearense catalog offers various types of rebar, which can be cut and bent according to your needs. Currently, the cutting and bending service is available in Belém, Pará, but will soon be offered in several regions of Brazil.

Now you understand the importance of steel cutting and bending in construction. By relying on the best supplier, you'll have no trouble finding the parts you need and providing the best possible service to your customers.

Are you looking for custom steel parts for your project? Then get in touch. request a quote.